The holy grail of the automotive vehicle fuel cell coating market is low-cost carbon coating exhibiting low contact resistance and long-term durability. TreadStone's patented DuraC coating product is a newly offered carbon-based coating that reduces the surface electrical resistance of metal components at a low cost. DuraC is the solution that meets the industry requirements of low contact resistance, long-term durability, and low cost.

DuraC

DuraC

DuraC

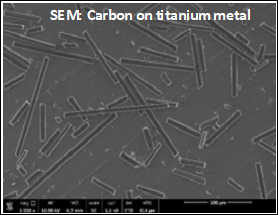

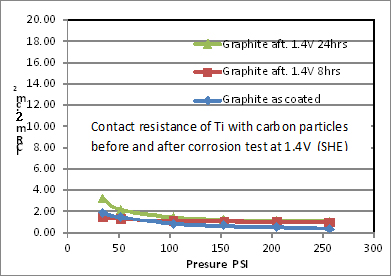

Currently, DuraC is being demonstrated on titanium metal electrodes used in flow batteries for long-duration energy storage. TreadStone's DuraC coating is a thin layer of carbon particles (20-50 ?m thick) used on the metal component surfaces where the carbon particles are bonded to the metal surface. The carbon particles serve as electrical contact points that achieve low electrical contact resistance. Test data indicates the DuraC coating can meet the performance requirements for flow battery applications. Long-term durability studies are underway.

The next phase of our development program is to use the DuraC coating for use on stainless steel, the preferred material used as bipolar plates for automotive applications. Current development work and testing should be completed by June 2023. In late 2023, TreadStone will have the capability to coated low volume samples for initial testing in commercial markets.